- NH-3MAA device for comprehensive evaluation from manufacturing to imaging performance

- NH-3NStandard system in the NH Series combining superior functionality with high cost performance

- NH-3SEStitching measurement technology making ƒÊm measurement of concavity of 60° or more

- NH-3SPHigh precision version with maximum measurement precision and resolution

- NH-4NIdeal for quality control of high density and increasingly large semiconductor products such as 8-inch wafers and lead frames

- NH-5NMakes high-precision measurement of large, heavy-weight goods such as precision molds with portal structures

- NH-6NDirect measurement of LCD patterns, large aspherical mirrors, etc.

MITAKA / RYOKOSHA

MITAKA / RYOKOSHA

NH-3N

This equipment has made complete non-contact, high precision, automatic measurement of shape, dimensions and surface roughness possible with a laser probe system. It provides multi-measurement functionality for a wide range of uses from R&D to quality control of the manufacturing line for photonic devices, semiconductor products, ultra-precision machining parts, etc. for which the market will demand smaller products with higher precision and lower costs.

This equipment has made complete non-contact, high precision, automatic measurement of shape, dimensions and surface roughness possible with a laser probe system. It provides multi-measurement functionality for a wide range of uses from R&D to quality control of the manufacturing line for photonic devices, semiconductor products, ultra-precision machining parts, etc. for which the market will demand smaller products with higher precision and lower costs.

Features

- Four years after first being sold, the NH-3, which has become a byword for non-contact height measurement, has evolved into the new NH-3N, implementing feedback on the functions of the high precision NH-3 SP.

- Experience the world of ultimate non-contact measurement which features auto focus functionality that is not affected by low reflectivity and completely non-destructive measurement, at the same time pushing the edge of precision for Z, X and Y measurements.

Specifications / Measuring Functions

Specifications

| Lens shape measurement (with laser probe) |

|

| Optical properties evaluation (with image processing) |

|

Measurement Examples

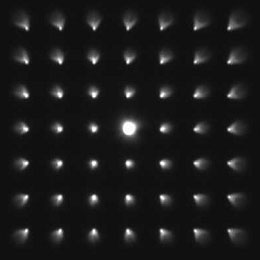

Aspheric lens coma aberration

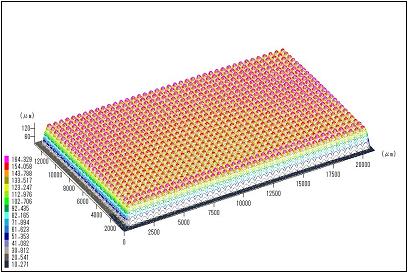

MLA 3D shape measurement result

Measuring Functions

3D shape measurement, cross-sectional shape measurement, roughness measurement, automatic measurement, various measuring functions